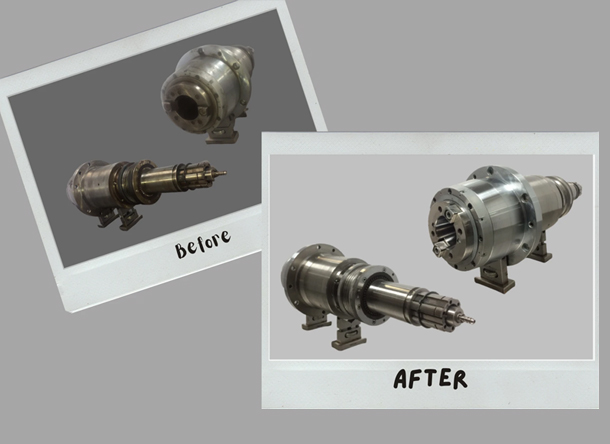

Tree VMC 1260

Spindle Inspection Analysis:

This spindle had heavy contamination throughout the front and middle bearing sets. The shaft I.D. taper showed signs of wear, run-out, and high and low spots in the taper. The drawbar had low pull force and fatigued disc springs.

Repair Performed:

Disassemble the spindle, evaluate failure mode, clean all parts, and inspect critical parts and features. Grind the shaft I.D. taper to clean up the low spots & remove the run-out. Rebuild the drawbar with new Belleville disc springs. Replaced the bearings, seals, and o-rings and rebuilt the drawbar with new Belleville disc springs. Run & balance.

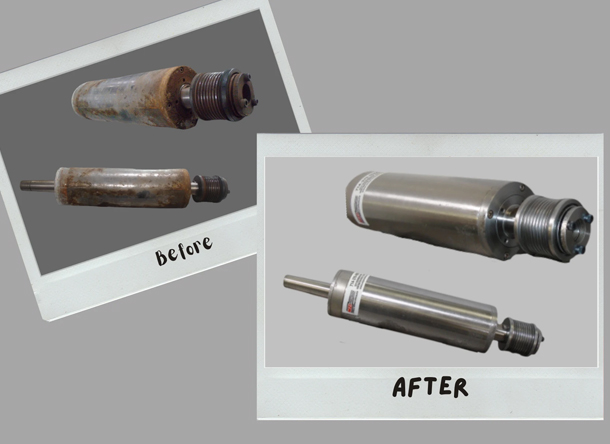

Disco Slicer DLS 35/35

Spindle Inspection Analysis:

This spindle had signs of rust & corrosion. Upon inspection, we found the spindle failed due to lack of lubrication. The bearing grease had been washed out. The shaft OD taper had minimal wear.

Repair Performed:

Disassemble the spindle, evaluate failure mode, clean all parts and inspect critical parts and features. Dust grind the shaft OD taper to clean and wear. Replaced all bearings, seals, and o-rings. Run & balance.

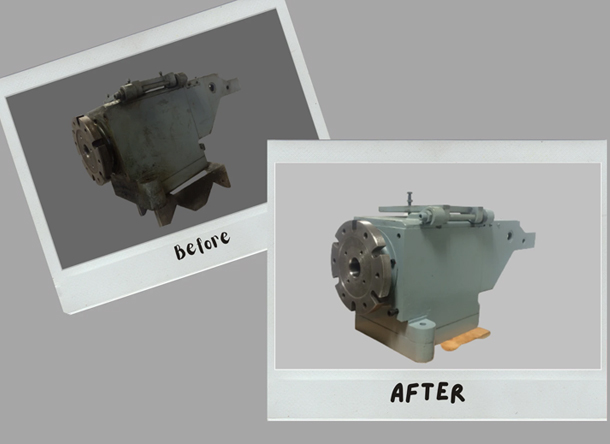

Heald 27A Headstock

Rebuild Specifics:

Inspection showed that the bearings had excessive grease, coolant, rust, and grinding sludge contaminants. The shaft bearing journals & housing bores checked out within specifications. We replaced all of the bearings, seals & o-rings.